Aluminum alloys and metallurgy

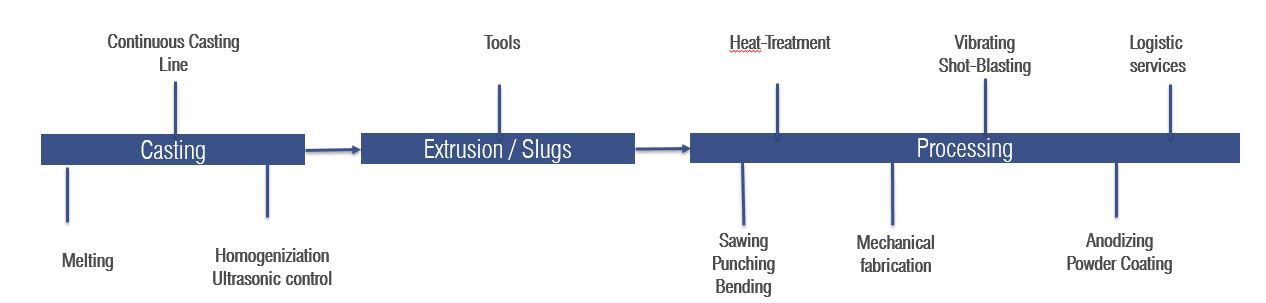

Aluminum manufacturing processes from a single source. From standard alloys to individual complete solutions.

In our in-house cast house, we operate a casting rolling conveyor system for the production of slugs, various melting and casting systems and vertical strand casting systems.

We produce billets with a diameter of 315 millimetres for the extrusion lines. The annual capacity of our strand casting system is around 40,000 tons. With modern testing methods in our metallurgical laboratory, as well as with the ultrasonic testing of the casted billets, we guarantee consistent high quality.

Aluminium can be used for many functions and in many forms. The choice of alloy is decisive here. It can influence the strength, flow properties, machinability and stability of the product.

Our customers can rely on our expertise when deciding the best alloy for them! If needed, we can also develop our own, also patented, alloys and/or modified alloys according to the requirements of our customers. Together with you, we test the functionality of these alloys in casting and extrusion tests.

Legierungsgruppen

Legierungsbezeichnungen

EN AW 1000er

1050A, 1070A, 1100, 1350A

EN AW 3000er

3003, 3004, 3102, 3103

EN AW 5000er

5005A, 5210, 5754

EN AW 6000er

6005, 6005A, 6056, 6060, 6061, 6063, 6082, 6082A, 6182, 6101B